The external wall cladding system has an impact on the overall building, bringing thermo-acoustic wellness inside and improving the external quality look in relation to the existing architectural context. The various features, performances and look of the external coating, vary based on the interaction between the materials making up this system. The choice of the cladding type (cement, plastic, ceramic, stone, metal) is made as a result of an architectural project that emphasizes the choices linked to form, functionality and look of the building. These aspects take on different meanings and priorities based on the coating. In general, an aspect influencing the type of coating is aesthetics, without neglecting the importance of the technical features of the cladding system, such as resistance to bending due to the wind and resistance to weather conditions. A notable aspect of these cladding systems is the dry installation with mechanical fixings. The ventilated faҫade is a particular kind of wall cladding that envisages the dry installation of panels of suitable thickness, maintaining a set distance to the pre-existing building.

In compliance with the UNI 11018 standard, the ventilated facade is “a type of advanced-display facade, in which the gap between the cladding and the building is designed so that the present air can float by the stack effect, in a natural or artificially controlled way, based on the season and /or daily needs, in order to upgrade its overall thermoenergetic performances”.

Therefore, the ventilated facade is a cantilevered system giving the building a new skin.

This structure consists of four layers:

1. Insulating continuous water-repellent layer, placed close to the existing structure;

2. Ventilation gap forming an air chamber linked to the outside through top and bottom airing vents (stack effect due to the difference of temperature between the air in the chamber and the outside);

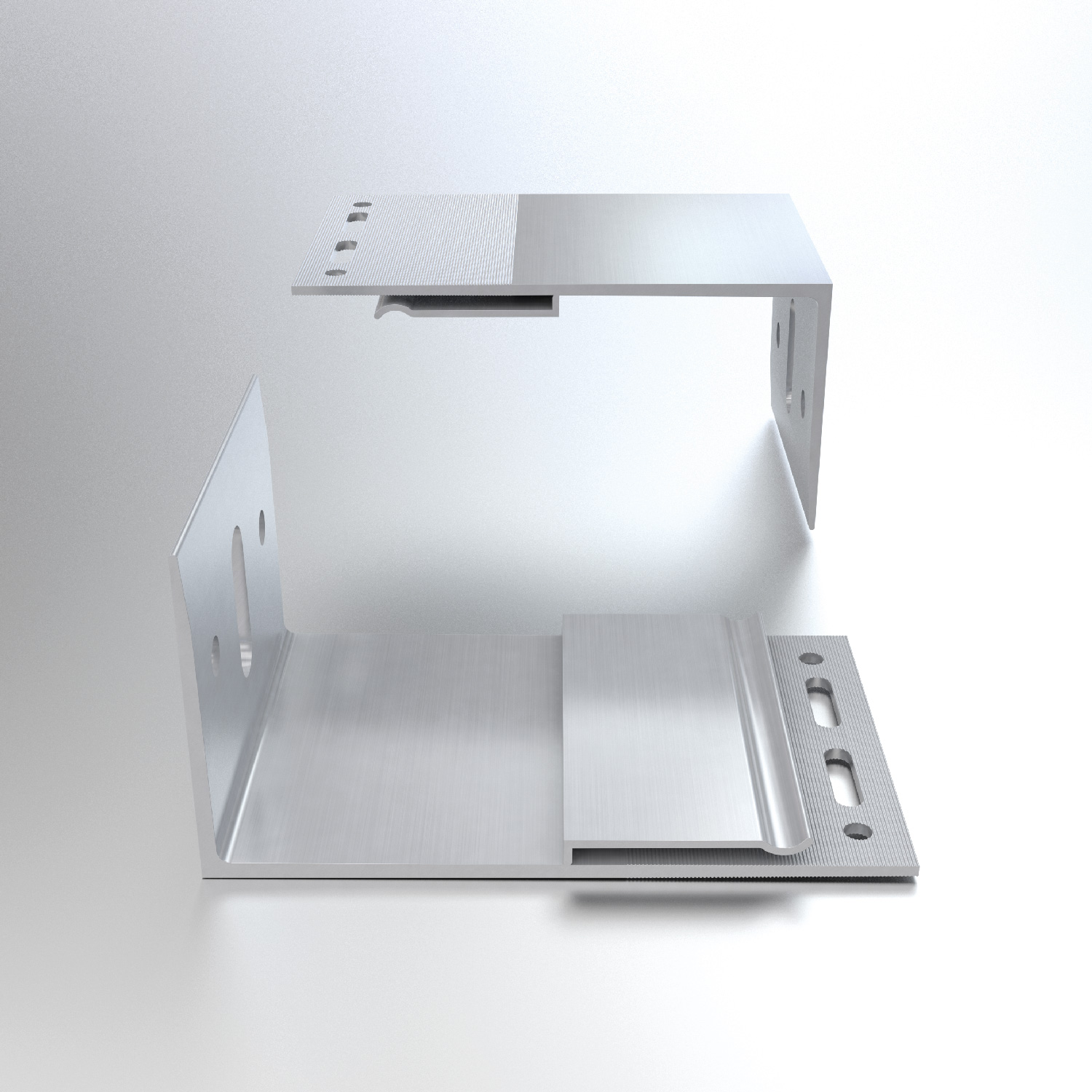

3. Substructure fixed to the existing wall by metal brackets. The anchoring systems could include visible or hidden hooks, fastening the rear of the coating panel to the supporting structure;

4. External skin.

EXTERNAL WALL PROTECTION from weather conditions keeping it dry and eliminating seepage risks and the deterioration of the external wall.

REINFORCEMENT OF THE TRADITIONAL INSULATION SYSTEM, eliminating thermal bridges and upgrading the energetic performances of the building.

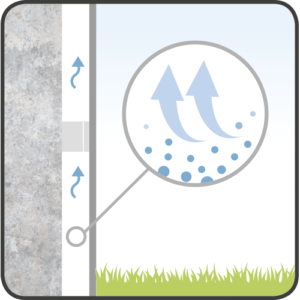

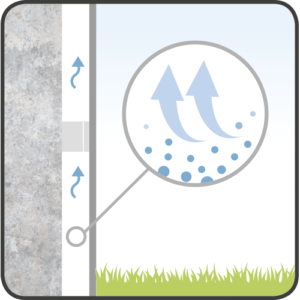

TRANSPIRATION OF THE FACADE, and elimination of moisture, thanks to the effective air flow from bottom to top in the airing gap.

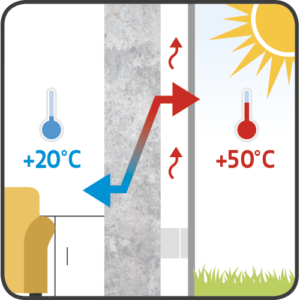

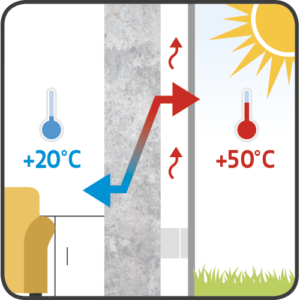

PROTECTION OF THE EXTERNAL WALL absorbing and reflecting solar energy. The heated air in the structure gap allows, thanks to the stack effect, to eject this air through the building top.

DRAMATIC REDUCTION OF THE CONDENSATION PHENOMENON with quick elimination of water vapour coming from the inside. Therefore, it keeps the skin of the existing building healthy in the wintertime.

ENDLESS POSSIBILITIES OF ARCHITECTURAL MAKE-UP of facade cladding, exploiting the aesthetic potential of the best products on the market, improving the thermo-acoustic wellness of the building.

DURABILITY– resistance to UV rays, stains and mould.

EASE INSTALLATION for every use purpose, both for new and pre-existing buildings.

EASY MAINTENANCE

The modular substructure allows the easy replacement of every single damaged sheet and quicker maintenance of the building itself.

EXTERNAL WALL PROTECTION from weather conditions keeping it dry and eliminating seepage risks and the deterioration of the external wall.

REINFORCEMENT OF THE TRADITIONAL INSULATION SYSTEM, eliminating thermal bridges and upgrading the energetic performances of the building.

TRANSPIRATION OF THE FACADE, and elimination of moisture, thanks to the effective air flow from bottom to top in the airing gap.

PROTECTION OF THE EXTERNAL WALL absorbing and reflecting solar energy. The heated air in the structure gap allows, thanks to the stack effect, to eject this air through the building top.

DRAMATIC REDUCTION OF THE CONDENSATION PHENOMENON with quick elimination of water vapour coming from the inside. Therefore, it keeps the skin of the existing building healthy in the wintertime.

ENDLESS POSSIBILITIES OF ARCHITECTURAL MAKE-UP of facade cladding, exploiting the aesthetic potential of the best products on the market, improving the thermo-acoustic wellness of the building.

DURABILITY– resistance to UV rays, stains and mould.

EASE INSTALLATION for every use purpose, both for new and pre-existing buildings.

EASY MAINTENANCE

The modular substructure allows the easy replacement of every single damaged sheet and quicker maintenance of the building itself.

All the elements that form a wall cladding system, including metal fixing tools, are subject to expansions and contractions depending on the type of material. Therefore it is necessary to take certain precautions, not putting panels and structure in close contact with each other, in order not to create tensions and differential motions that can break the sheets.

A ventilated facade, to be considered as such, has to meet specific technical requirements:

CLADDING WEIGHT

Weight is important to calculate the structural parts of the building and when choosing the most suitable installation method, considering a higher weight for stone coating in comparison with metal ones.

ELEMENTS DIMENSION

A correct ratio between the surface and the thickness of each element is necessary to support the weight thanks to the anchoring devices. The number of anchors will depend on the type of system adopted and on the area occupied by each element.

JOINTS

It is the element representing the continuity between panels and omega feet, subject to settlement effects, like elastic-plastic subsiding and thermal deforming between the coating wall and the load-bearing structure. In general, open at least 6 mm wide joints are used.

ELASTIC DEFORMATION OF THE STRUCTURE

Every load-bearing structure is subject to an elastic deformation when loaded. As a result, if the cladding is fixed tightly, without possibility to move, it is forced to follow the elastic deformation undergoing stress and possible breaking of the elements.

WIND EFFECT

The wind represents one of the main dangers for the static safety of the wall cladding; most stressed sheets are the ones in proximity of the edges, so it is necessary to accurately test and calculate them to quantify the wind action.

SEISMIC ACTION

The evident deformations to which the load-bearing structure of the building is subject require particular flexibility performances, both for the anchors and the cladding elements to prevent them from breaking and their shreds from coming off and falling from above.

THE ANCHORING SYSTEM

This is the most delicate and essential part of the whole system as its stability depends on the anchoring method and the kind of anchoring systems. This will be chosen and calculated based on the structure they will be fixed on, the weight and the dimensions of the sheets and the external actions that affect the cladding and the building (wind, earthquake, building settlement).

Le staffe Anchoriv vengono realizzate in 4 lunghezze standard:

90 – 120 – 150 – 180 mm.

Il nostro ufficio tecnico è a disposizione per studiare e sviluppare alternative di geometrie di materiali.

Resistente e leggero: l’alluminio è uno dei materiali con il miglior compromesso tra resistenza e leggerezza e pesa esclusivamente 1/3 dell’acciaio.

100% riciclabile: l’alluminio è storicamente riciclato e riutilizzato. Si conta che il 75% dell’alluminio mai prodotto è attualmente ancora in uso, avendo subito infiniti cicli di riciclo.

Flessibile: le caratteristiche di alcune leghe di alluminio, in particolare la flessibilità, sono uniche tra tutti i metalli presenti in commercio.

Non combustibile: l’alluminio mantiene le sue caratteristiche strutturali fino anche a 250°, e fonde esclusivamente attorno ai 660°.

Aluminium is the best choice between resistance and lightness; it weights just one third of steel.

Aluminum is historically recycled and reused. It is estimated that 75% of the aluminum ever produced is currently still in use, having undergone infinite recycling cycles.

The characteristics of some aluminum alloys, in particular the flexibility, are unique among all the metals on the market.

Aluminum maintains its structural characteristics up to 250 °, and melts exclusively around 660 °.

Compila i campi sottostanti, ti risponderemo entro poche ore.